The LED display industry has undergone several innovation in terms of encapsulation, from DIP to SMD, and now moving towards COB and MIP. Key aspects such as driver ICs, LED chips, substrates, and chip transfer technology are also constantly evolving. As technology advances, the miniaturization of pixel pitch continues, resulting in increasingly refined display performance.

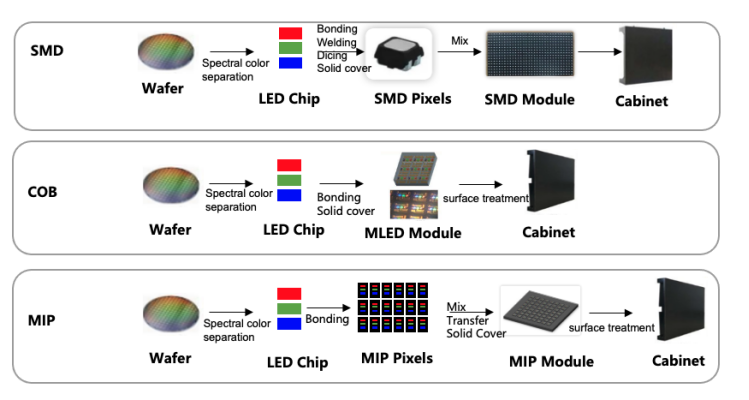

1. Encapsulation Technology

SMD : SMD (Surface-Mount Device) uses SMT (Surface-Mount Technology) to mount light-emitting chips on a PCB substrate. As pixel pitch decreases, SMD now faces challenges in achieving finer pitch.

COB and MIP : COB (Chip-on-Board) and MIP (MicroLED in Package) are two of the latest encapsulation in the LED display industry, aimed at further reducing pixel pitch and achieving higher integration and display precision. COB directly mounts the LED chip onto the substrate and encapsulates it with transparent resin, significantly improving pixel pitch miniaturization and display performance, especially for ultra-fine pitch displays below P0.6. MIP increases integration to achieve finer display effects, especially suitable for smart wearables, mobile devices, and high-precision commercial displays. The combination of COB and MIP drives the LED display industry toward higher precision and smaller pixel pitch, giving them a competitive edge in more application scenarios.

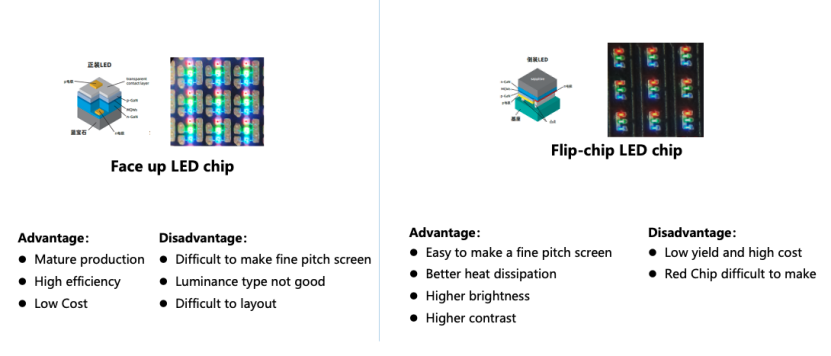

2. LED Chips

LED chips are the core component of LED display technology, and their evolution directly impacts display performance and applications.

- Face-up Chips: Traditional face-up LED chips have mature production processes, high efficiency, and low cost. However, as pixel pitch continues to undergo miniaturization, limitations of face-up LED chips become apparent, such as difficulty in further reducing pixel pitch, poor Luminous efficiency, and difficult to layout.

- Flip Chips: Flip LEDs allow for smaller pixel pitches, provide better heat dissipation, and support high current driving for increased brightness. Since flip LEDs do not require bonding pads on the substrate, more black area is displayed, significantly enhancing contrast. However, flip-chip technology requires high placement accuracy during bonding, leading to lower yield and higher costs.

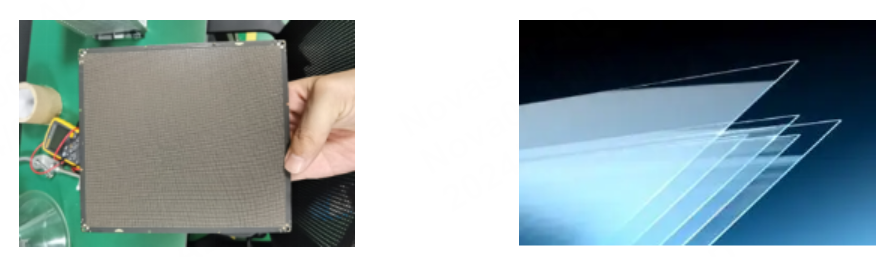

3. Substrate Technology

The substrate is the foundation of LED display modules, and its material and processing methods directly influence display performance and applications.

PCB Substrate: PCB substrates are widely used in LED displays and are known for their high maturity and good heat dissipation. However, when applied to ultra-fine pixel pitches below P0.6, PCB substrates face difficulties in circuit design and drilling accuracy.

Glass Substrate: Glass substrates are increasingly favored to address the challenges of smaller pixel pitches. Glass substrates offer better rigidity and precision, making them ideal for small to medium-size displays. They can also directly integrate TFT circuits or Micro-IC drivers, making them an optimal choice for high-end displays.

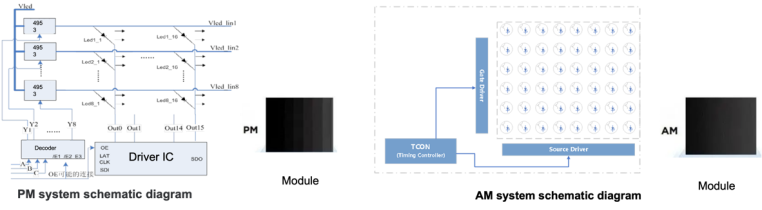

In the current industry, the combination of glass substrates and AM (Active Matrix) driving has become a common technical route, while PCB substrates paired with PM (Passive Matrix) driving remain the mainstream technology.

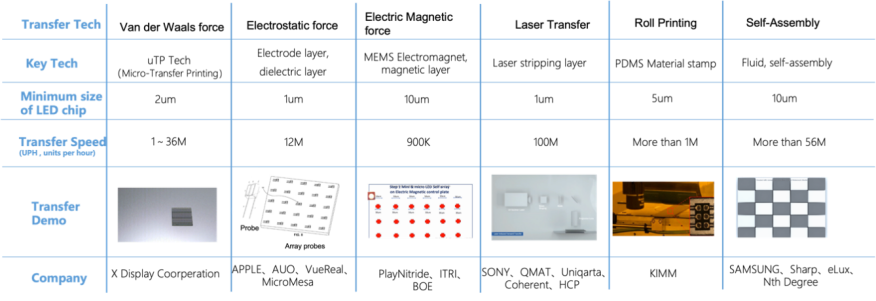

4. Transfer Technology

As pixel pitch miniaturization progresses, traditional chip transfer methods can no longer meet the efficiency demands of production, leading to the development of mass transfer technology.

Mass Transfer Technology: Mass transfer technology aims to quickly and efficiently transfer a large number of micron-sized LED chips to the substrate. Common mass transfer methods include Van der Waals force transfer, electrostatic transfer, magnetic transfer, laser transfer, and roll printing.

- Van der Waals Force Transfer: Uses weak Van der Waals forces to achieve chip transfer, suitable for high-density integration of small chips.

- Electrostatic Transfer: Chips are transferred from the original substrate to the target substrate via electrostatic adsorption, providing high transfer accuracy.

- Magnetic Transfer: Utilizes a magnetic field to transfer chips, applicable to specific types of LED chips.

- Laser Transfer: Laser lift-off technology uses precise laser pulses to transfer chips from the source substrate to the target substrate, offering extremely high precision and yield.

- Roll Printing: A roller transfers large numbers of chips onto the substrate, suitable for mass production.

The rapid development of mass transfer technology is expected to reach large-scale application by 2025, significantly driving the adoption of MLED display technology.

5. Driver Method

· PM Driver Method: PM (Passive Matrix) driving is a traditional LED display method. Each LED chip consumes power in the milliamp range, with low integration and high power consumption. At low brightness, PM driving is prone to flickering, affecting the viewing experience.

· AM Driver Method: AM (Active Matrix) driving assigns an independent driver circuit or driver IC to each pixel, avoiding flickering at low brightness levels. Power consumption is controlled in the micro-amp range, with higher integration and lower power consumption, making AM driving the mainstream choice for future high-end displays.

6. Driver IC

Driver ICs are critical components of LED displays, and their evolution directly affects display performance and viewing experience.

· PWM Driver IC: PWM (Pulse Width Modulation) driver IC is a common LED display driving method that controls pixel brightness by adjusting the pulse width of the current. Although PWM driver ICs offer high grayscale control precision, they tend to cause flickering at low grayscale levels due to low refresh rates. Additionally, PWM driver ICs are limited in dynamic range, making it difficult to achieve higher contrast and more refined display effects.

· PAM+PWM Hybrid Driver IC: To address the issues of flickering at low grayscale levels and insufficient dynamic range, NovaStar has introduced the world’s first mass-produced driver IC based on PWM+PAM (Pulse Amplitude Modulation) hybrid driving technology. This technology combines the advantages of PWM and PAM, controlling current amplitude without altering the high-level duration, thereby maintaining a high refresh rate at low grayscale levels. This hybrid driver IC not only improves display performance but also significantly reduces power consumption, ensuring excellent image quality even at low brightness and offering a higher dynamic range.

The LED display industry is rapidly evolving towards smaller pitch displays, with new packaging technologies such as COB and MIP achieving even smaller pixel pitches. The support of mass transfer technology has significantly enhanced manufacturing efficiency for displays. Additionally, innovations in driver IC technology, particularly the advent of PWM+PAM hybrid driver ICs, have further improved display quality and energy efficiency. As these technologies mature, LED displays are poised to dominate a wider range of application scenarios, advancing into both commercial and consumer markets, and meeting the increasing demand for high-quality, low-power display products.