LED displays revolutionized modern visual technology, with applications ranging from advertising billboards to indoor digital signage. However, not all LED screens are created equally. The three most common types of LED packaging method used in display installations are DIP, SMD, COB, and MIP. Each of these technologies has distinct features that make them suitable for different environments and purposes. In this article, the differences between these four technologies will be explored and how the installation methods impact LED screen performance will be discussed.

1. DIP (Dual In-line Package) LEDs

DIP (Dual In-line Package) is the oldest and most traditional LED technology. This method involves mounting three separate diodes—red, green, and blue—on a single circuit board, with each diode having its own protective casing. These diodes are arranged in an inline package, which is why this technology is called DIP.

Image by https://ledsino.com/dip-smd-cob/

Installation Method:

In DIP screens, the diodes are mounted through the circuit board using traditional pin-through-hole technology, making the installation process relatively simple. However, because of the large size of each individual diode, DIP screens are bulkier and thicker than other LED types. The installation may require more space and robust support, especially for large outdoor setups.

Characteristics of DIP LEDs:

- Brightness: DIP LEDs are known for their high brightness, making them ideal for outdoor displays where visibility in sunlight is critical.

- Durability: The individual packaging of the diodes makes DIP LEDs highly resistant to weather conditions, especially for outdoor scenarios.

- Lower Pixel Density: Due to the physical separation of the diodes, DIP displays often have lower pixel density compared to more advanced LED technologies. This limits their usage in applications requiring high resolution, usually used for P6, P8, P10, P16, P20 outdoor screen.

- Way of soldering: By soldering diode pins on the PCB board, the DIP diode becomes much durable. The solder joint issue does not easily come up during transportation or using especially in the extreme external conditions.

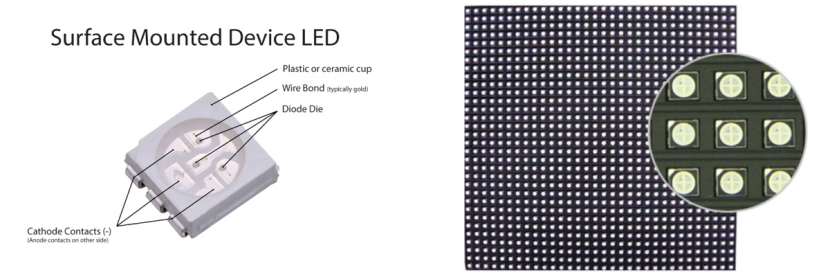

2. SMD (Surface-Mounted Device) LEDs

SMD technology is a more recent advancement in LED displays. Unlike DIP, SMD packaging integrates all three diodes (red, green, and blue) into a single small chip which is mounted directly onto the surface of the circuit board. This results in more compact, efficient, and higher-resolution displays.

Image by https://ledsino.com/dip-smd-cob/

Installation Method:

The surface-mounted characteristic of SMD diodes simplifies the installation process, as the chips can be directly soldering fixed onto the circuit board without the need for pin-through-hole mounting. This allows for thinner, lighter screens that are easier to transport and install, especially in indoor environments. SMD screens are often modular, allowing for faster installation and maintenance.

Characteristics of SMD LEDs:

- Compact Size: By integrating all three diodes into one chip, SMD LEDs offer higher pixel density, making them ideal for indoor displays requiring sharp resolution. SMD components can be made smaller and thinner because they are only soldered to the surface of one side of the circuit board.

- Brightness and Energy Efficiency: SMD LEDs are brighter and more energy-efficient than DIP LEDs, although they may not achieve the same level of brightness in outdoor environments.

- Versatility: SMD technology is used in both indoor and outdoor LED screens, although it is more commonly found in indoor applications due to its higher resolution capabilities.

- Colors: SMD screens usually use 3-in-1 LEDs. With one RGB 3-in1 LED unit per pixel, there are three tiny led chips sealed inside a single part. Therefore, the color blends better, and the image appears sharper.

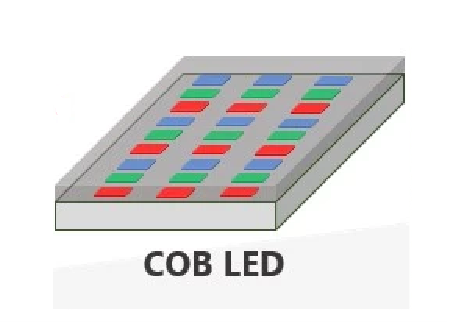

3. COB (Chip on Board) LEDs

COB (Chip on Board) is the latest LED technology, taking integration to the next level. In COB displays, multiple LED chips are mounted directly onto a substrate, forming a cohesive module. These chips are densely packed together, creating a more seamless and uniform display surface. Moreover, COB screens are even thinner and lighter, offering greater flexibility in installation. These screens can be used in tight spaces or integrated into complex shapes and surfaces. The modular nature of COB panels makes them easy to install, maintain, and replace.

Image by https://ledsino.com/dip-smd-cob/

Installation Method:

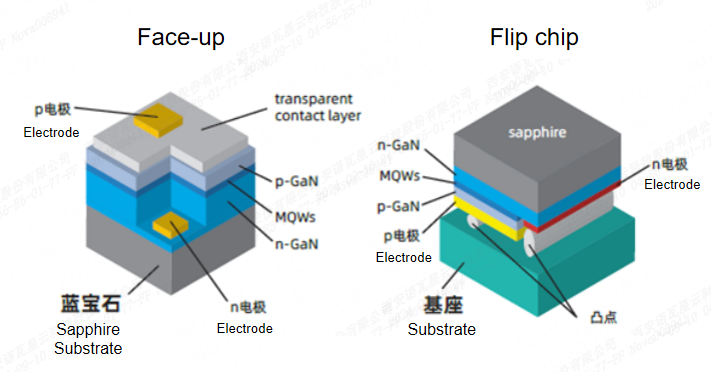

COB packaging process offers two different installation methods: the Face-up method and the Flip-chip method.

Face-up method: The COB (Chip on Board) chip is installed directly onto the PCB with the chip exposed on the front. In this process, the chip is attached and secured to the front of the PCB and then electrically connected using methods such as soldering

Flip-chip method: The COB chip is flipped and installed on the back of the PCB, with the back of the chip attached to the board. This means that the chip is not directly exposed on the front of the PCB but is connected to the PCB through its back.

The Face-up method are usually better at heat dissipation as the chip is exposed. while it is easier to be effected by the environment. Compared with Face-up method Flip chip method not only eliminates the wire bonding process and simplifies the production process, but also effectively solves the problems of wire virtual soldering and broken wires, as well as metal migration in Face-up method, greatly improving the LED lamp’s reliability. Moreover Flip chip method does not need physical space for wiring and can achieve higher pixel density.

Characteristics of COB LEDs:

- High Pixel Density: From the physical space size, COB package in the design of lamp bead diameter is no longer limited by the size of the bracket. COB technology offers the highest pixel density of the three, making it the best choice for high-resolution displays.

- Seamless Display: Due to the close packing of the LED chips, COB screens have fewer gaps between pixels, resulting in a smoother image and more consistent color.

- Thinner Screens: COB displays are extremely thin and lightweight, making them ideal for applications where space is limited or a sleek design is essential.

- Durability: COB products are directly encapsulated with led chips in the concave position of the PCB board, and then cured with epoxy resin. The epoxy coating, no exposed feet, can play a waterproof, dust-proof, anti-static and other functions. When in contact with water, a wipe with a cloth is good. The outdoor module, which is not afraid of water at all, has no effect on the screen body. After a period of use, the dust of the screen body can be wiped directly with a cloth, and the dust is cleaned directly from the smooth surface

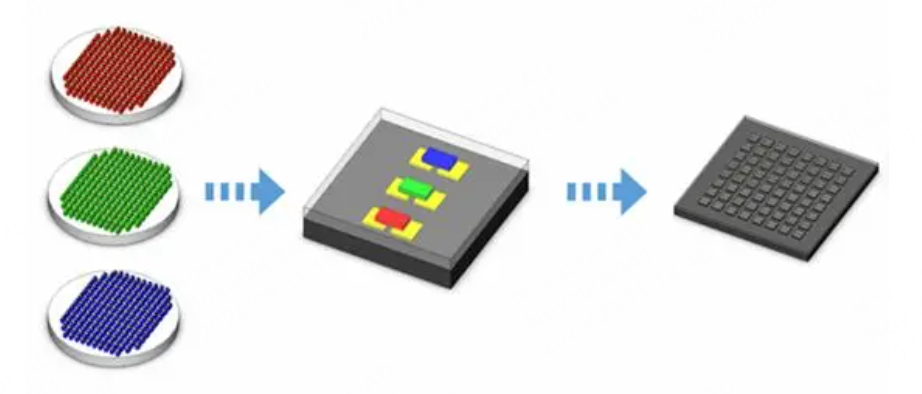

4.MIP(Micro LED in Package) LEDs

Due to the increasing demand for light source brightness and smaller pixel pitch in the market, the MIP(Micro LED in Package) packaging method comes out.

Image by https://zhuanlan.zhihu.com/p/671938798

Installation Method:

MIP is a new packaging method based on Micro LED. It is consisted by Micro LED and discrete devices. The Micro LED chip is transferred to the substrate using mass transfer technology. And then it is cut into single or multi-in-one small chips. These chips would be split and mixed later. After the chip placement process and screen processing The surface of the body is covered with film to complete the production of the LED display.

Characteristics of MIP LEDs:

- High Pixel Density (Ultra-Fine Pixel Pitch): Supports pixel pitches below 1mm for high-resolution, detailed imagery.

- Durability: LED encapsulation provides protection against environmental factors like dust, moisture, and impacts.

- Enhanced Brightness and Color: Delivers high brightness with uniform color accuracy and minimal distortion.

- Production Chain: MIP is a typical independent lamp bead package that is compatible with downstream surface mount production processes, making MIP highly flexible in testing, repair, and process tolerance. Downstream products also become more flexible due to the use of traditional surface mount processes and the ability of single specification MIPs to meet the characteristics of multi specification terminal products

Conclusion

When it comes to LED screen technology, choosing the right type—DIP, SMD, or COB—depends on the specific needs of the application.

- DIP is ideal for outdoor installations that require high brightness and durability.

- SMD offers a balance of brightness, energy efficiency, and compact design, making it versatile for both indoor and outdoor use.

- COB is the cutting-edge choice for high-resolution, seamless displays, especially in indoor environments where clarity and design are paramount.

- MIP is also an advanced technology designed for ultra-high-resolution displays with fine pixel pitches, offering exceptional image quality, durability, and efficient thermal management. At the same time, it can also use the traditional surface mounting process of SMD production lines. But this is also the biggest factor limiting the development of MIP towards smaller pixel pitch.

Understanding the differences between these LED technologies ensures you make the right choice for your display needs, whether you are installing a large outdoor billboard or a high-definition indoor screen.

See you all next page.

NovaStar Innovation