COB Display: Growing Up – By NovaStar Innovation

In the ever-evolving landscape of LED display technology, the key trends are high integration and miniaturization. Among the pathways explored in the realm of Mini & Micro LED fine-pixel display technology, Chip-On-Board (COB) packaging technology stands out for its significant advancements in display performance and form, validated through continuous market testing. The path taken by COB displays has been one of transformation in an environment of perpetual scrutiny and observation.

As we approach the midpoint of this year, the shipments of COB panels have been steadily increasing. With the continuous refinement of production processes, COB displays have been progressively replacing conventional indoor fixed installations. The current state of market applications is a testament to the growing recognition of COB displays, with instances of their use in outdoor display projects at the Hangzhou Asian Games in China.

Furthermore, the overseas market has witnessed practical applications of COB displays in consumer markets such as home theaters. This underscores that COB display technology has garnered substantial market recognition this year.

Under the influence of the trends in high integration and miniaturization, the solutions supporting COB panel displays have achieved continuous breakthroughs, particularly in grayscale, color, and display uniformity.

1. Grayscale and Color

While COB display manufacturers can adjust the brightness standards for shipments based on customer requirements, typical standards range from 600 nits to 900 nits. As a result, the grayscale of COB displays usually falls between 13-bit and 14-bit. However, scenarios demanding exceptionally high image quality often necessitate 15-bit to 16-bit grayscale levels, a threshold that standard COB displays seldom meet.

To meet market demands related to grayscale, NovaStar has collaborated with COB display manufacturers to integrate Image Booster technology into the standard production process. This integration has effectively addressed these requirements. The Image Booster encompasses three primary technologies: 22bit+, Fine Grayscale, and Color Management.

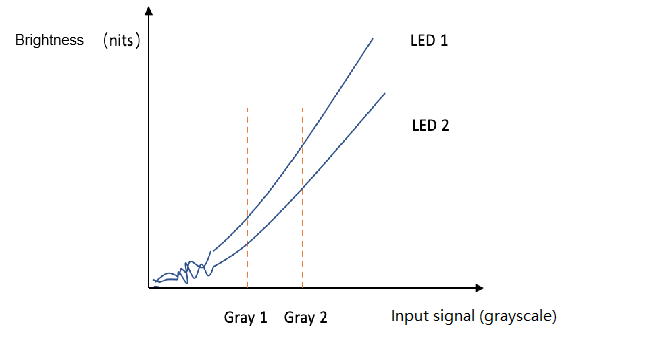

The 22bit+ technology is specifically designed to compensate for the shortfall in grayscale levels and suboptimal transitions in LED displays.

Building on the 22bit+ technology, Precise Grayscale technology has resolved issues such as inaccurate grayscale and abrupt transitions.

Lastly, with the inclusion of Color Management functionality, COB displays can meet the standard color gamut requirements for various application scenarios.

2. Display Uniformity

As is well-known, non-uniformity is a common feature in LED displays, necessitating fundamental steps in the COB panel production process for its resolution. Firstly, NovaStar has developed the Demura equipment, which seamlessly integrates into COB panel production lines. This equipment facilitates a smoother production process, simplifies installation, and enhances value for both COB display manufacturers and customers.

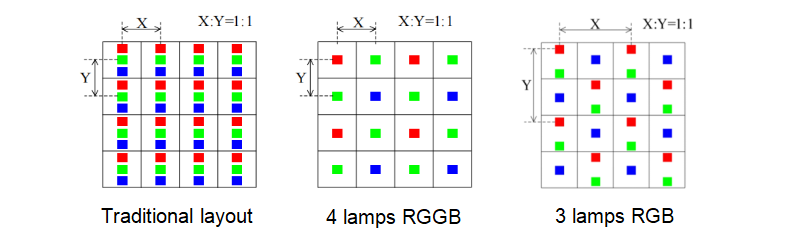

Moreover, NovaStar advocates full-screen calibration to meet the stringent on-site display requirements, with the widespread application of the C3200 scientific calibration system. This system’s value has been increasingly recognized by end customers. It offers precise collection and processing of brightness and chroma data for RGB luminescent chips, owing to the unique X, Y, and Z filters.

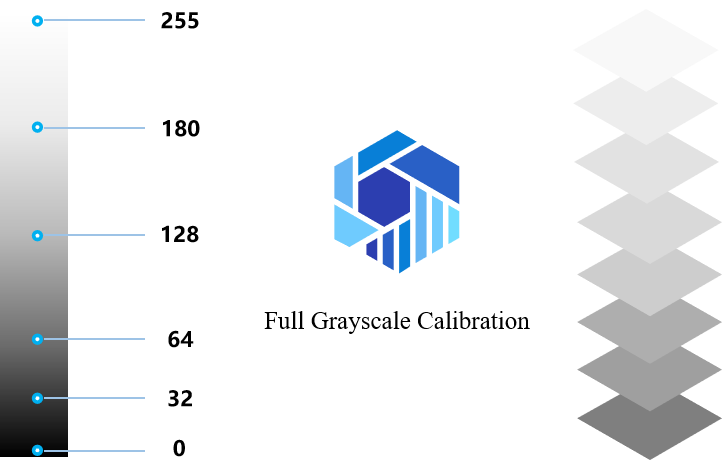

In indoor application scenarios for COB displays, there is a comprehensive focus on display uniformity across various grayscale levels. Traditional single-layer calibration is no longer sufficient to meet customer demands for uniformity within a broader grayscale range. Hence, NovaStar’s innovative full grayscale calibration function finds wide application in the high-end display market. In conjunction with the C3200 for collecting brightness data across different grayscale levels, NovaStar’s calibration system generates unique calibration coefficients for each grayscale ranging from 1 to 255.

3. Drive Mode

In the realm of COB display panels, the choice of drive mode plays a crucial role. For projects with P0.7 or P0.9 specifications, such as studios, film production, or those requiring high signal scanning, COB displays with scan type of less than or equal to 20 scans are often preferred. In this context, the adoption of conventional 16-channel driver chip designs can result in densely packed chip layouts on the module’s rear side.

To address the demands of highly miniaturized LED displays, an alternative to conventional 16-channel driver chip designs has gained widespread application in high-end projects. This integrated driver chip combines more channels to simultaneously process row and column drives displayed on COB panels, offering clear advantages in the design and application of lower scanning modules.

4. Exploring New Avenues

In the realm of Mini & Micro LED applications, COB displays were initially perceived as cost-prohibitive, deterring many medium-sized and retail projects. However, to make COB displays more accessible, COB display manufacturers have increased their production capacity and introduced the concept of virtual pixels, however, this is not marking a departure from history’s path. This change is motivated by two primary factors.

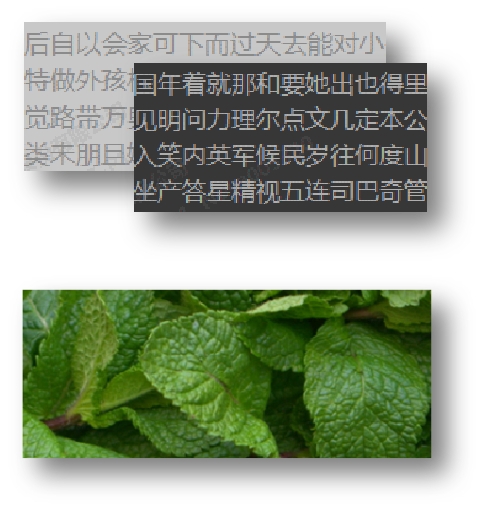

Firstly, project bidding often imposes restrictions based on PPI indicators. Smaller pitch COB displays come at a higher cost with lower yield, making the introduction of virtual pixels, referred to as “sub-pixels” by NovaStar, a more feasible solution to meet PPI indicator requirements.

Secondly, COB panel manufacturers are focusing on reducing manufacturing costs to benefit end customers. Acknowledging the significant concerns of most end customers regarding sub-pixel display quality, NovaStar has leveraged its unique pixel enhancement software and hardware solution to effectively meet the application needs of the majority of customers for COB displays.

Pixel Enhanced Algorithm

In summary, NovaStar is at the forefront of providing diverse solutions for COB display applications in various high-end fields, creating value for all stakeholders involved.

If you try to learn more about COB, please follow us.

See you all next page.

NovaStar Innovation