The Development of LED Display Industry-By NovaStar Innovation

LED screens are everywhere. From the streetlight outside of our house to the LED screen installed outside of the shopping mall, from the billboard alongside the highway to the LED screen inside a conference room , LED screens already penetrate into our daily lives.

LED screens also have been evolved with economic growth. If you look at the last few decades history of LED screen, the development is highly related with packaging and RGB chip technology. It separates into three stages as below.

1. DIP era (Dual in Package)

Full color LED screen came out with DIP package firstly in 1990s. It spreaded quickly in outdoor advertising area for high brightness and vivid colors. Even now, DIP LED screen is still the most popular product for outdoor billboard business.

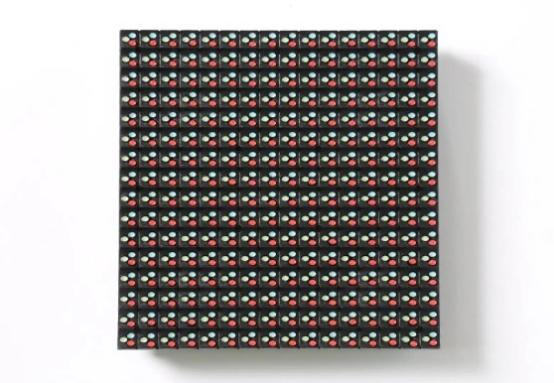

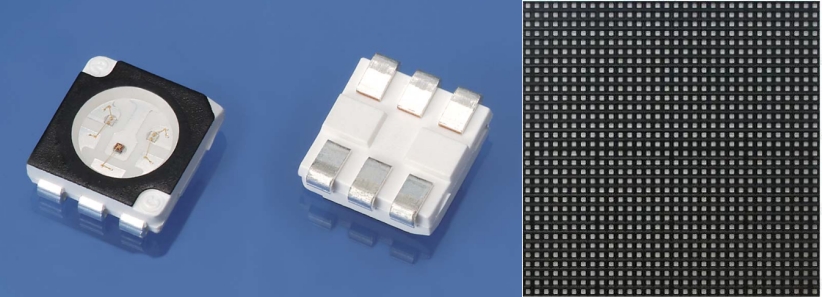

2. SMD era (Surface Mounted Device)

In 2000s, SMD package LED were invented. It’s high compact and cost-effective. When the pixel pitch of SMD LED screen goes under P2.5, the viewing distance of can be closer. So the indoor application are booming, like enterprise lobby, shopping malls, control rooms, churches, museums and etc. LED screen business grows dramatically in this era. It still covers the market between P1.5 to P3.0 application. Most of LED screens in our daily life are probably SMD ones.

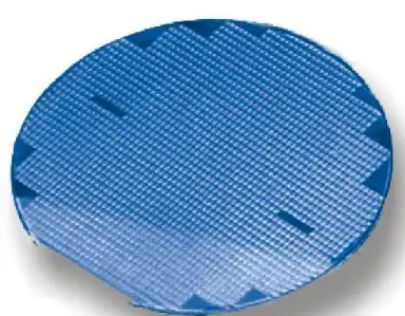

3. COB/COG era (Chip on Board/Glass)

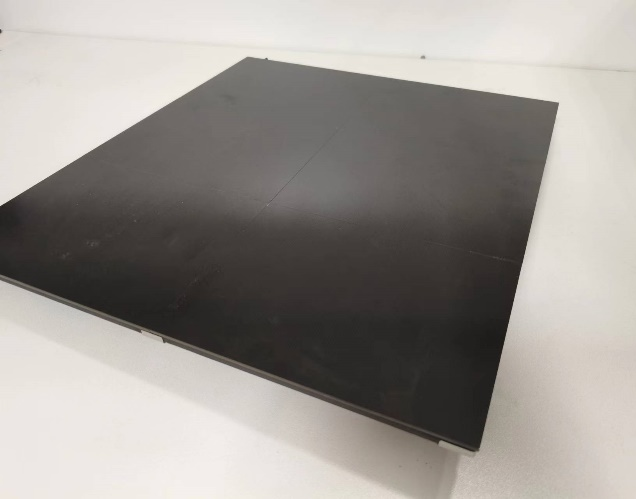

When LED screen business keeps expanding, especially for fine pitch LED screen customer, they have higher requirement about LED performance and visual experience. COB/COG screen stands out due to its inborn characteristics, like smooth surface similar as TV, surface light source display (with better visual experience and view angle) and high contrast. In this case, some end uers think COB/COG LED screen will be a new future of this market.

Technically speaking, COB/COG is a method of assembly that involves directly mounting an array of LED chips on printed circuit board or glass. This different packaging method brings a huge change of LED screen visual experience.

1. Surface Light Source

When COB produces, after mounting LED chips on PCB board, it will be covered with continuous epoxy layer and film. Without interference from surrounding plastics holder, COB light comes out from the LED chips omnidirectional as follows.

When COB LED chips mounted on the PCB board, Novastar scientific camera calibration can eliminate the non-uniformity due to color casting which makes LED chips brightness and chroma performance the same.

Eventually, the continuous surface light source is more eye friendly without granular sensation as following picture.

2. LED Chip Package

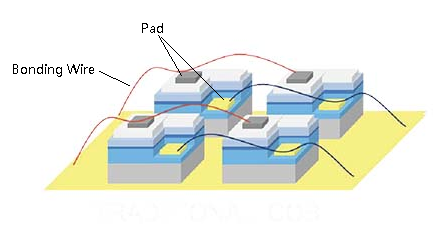

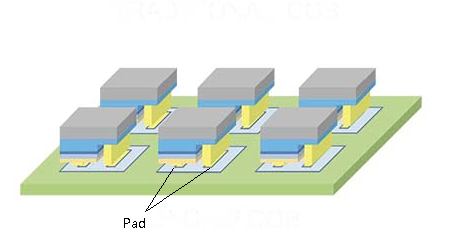

Traditional face up LED package is widely used in SMD products. The electrode pads locate on top of LED structure, connecting to PCB board with one wire-bond(Golden wire or Copper wire) for each electrode pad. Its schematic diagram shows as Figure 1a.

Flip-chip package shows as Figure 1b will save steps of wire bonding. The electrode pads will be directly connected to PCB board, which results in a higher effective luminous area under same chip size. As there is no bonding wire over light path block the light.

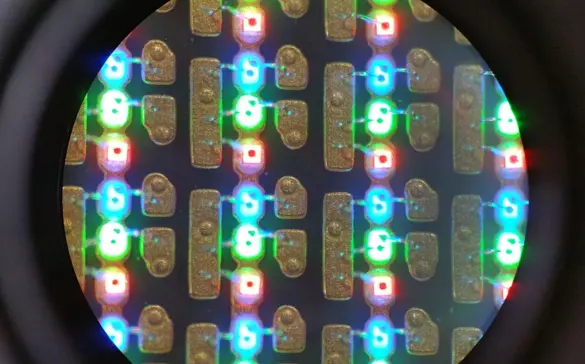

Figure 2(a) and 2(b) show the real picture of face up package and flip chip COB respectively. Flip chips save more PCB solder pad space and leave them as total black.

This is one of the reasons why flip chip LED screens have higher contrast.

Currently, LED screen is not limited with business application scenario. It has potential to enter consumer market, like home cinema, vehicle dashboard display, smart wearable, mobile display and etc.

With all the introduction all above, we can see where the entire LED industry goes to. Pixel pitch gets smaller, application scenario becomes wider.

If you would like to know more, for example, Pros and Cons between SMD and COB, why COB screen side view without perfect uniformity, how to calibrate a COB screen, please follow us.

See you all next page.

NovaStar Innovation